MCE-071 Fuel Filter

· NO.: 483GB471M

· Size: Φ110*263

· Thread: M30×1.5

· Application: Mack Engines, Trucks

· Reference number:

MACKS: 483GB471M

FLEETGUARD: FF5382

FRAM: P8050

BALDWIN: BF7657

DONALDSON: P554471

Lead Time: Inventory items take 1 to 5 days, while manufactured items take 45-60 days, depending on your order.

Warranty: 2 years warranty, 80000 kilometers

High efficiency diesel filter

The high pressure common rail system (HPCR) is mainly used in the diesel oil filtration system above Euro three. It is generally equipped with two-stage filtration. The pre filter filters most of the water and large particles of impurities, and the fine filter filters the small particles of impurities.

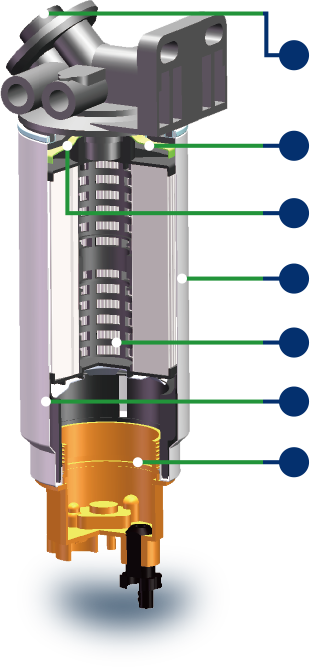

Filter Base: the hand pump is convenient for users to replace the Fuel-water separator, which can smoothly discharge the air in the fuel circuit, and ensure the smooth filtration of the filter and the normal operation of the engine.

Screw cover plate: it has enough strength, screw thread extrusion process, accurate size, beautiful and durable.

Sealing ring: HNBR material, oil resistance, temperature resistance up to – 40 ℃ ~ 140 ℃, stable performance, strong aging resistance.

Filter paper: imported Ahlstrom filter paper, higher filtration efficiency and fuel-water separation efficiency, multi-layer high dust capacity, extend the filter’s lifespan.

Central tube: no metal filter element design, ensure no rust.

Body or housing: high quality galvanized steel, high quality, long service life.

Transparent water collecting cup: the separated water can be clearly seen, which is convenient for users to draw off the water in time. The water collecting cup provides different types of interfaces, and can be used for electric heating to prevent wax deposition under low temperature of fuel oil; it can be matched with sensors to remind users of timely drawing off the water.

Diesel pre-filter

GaoHong diesel pre filter (also known as fuel-water separator) can effectively reduce the corrosion of water in the fuel on the injection system and protect your engine comprehensively. Multi-layer composite filter material is used for pre-filtration: the filter material has the special function of lipophilic and hydrophobic. When the fuel passes through the filter paper without barrier, the water in the fuel is blocked, and the fuel-water separation is realized by further water droplet accumulation and sedimentation.

Separator performance: the fuel-water separation capacity of the product is more than 95%.

Fuel or diesel filter

GaoHong fuel or diesel fine filter ensures that clean fuel enters the fuel injection system, so as to prevent premature wear of related parts of the injection system. Meanwhile, it improves engine power, effectively reduces fuel consumption and improves exhaust emissions.

Performance of diesel fine filter: the filtration efficiency of diesel fine filter is more than 98.6% for particulate impurities ≥ 4 μ m (c).

Multi-layer composite filter paper

GaoHong fuel or diesel fine filter (pre-filter and fine filter) adopts multi-layer composite filter paper, which adapts to the quality of Chinese diesel, has high-efficiency filtration performance, and meets the requirements of high-pressure common rail system such as Bosch, Delphi, Denso, fresh air of Euro Three and above engines.

Technical equipment

Automatic spraying equipment

The whole line adopts stainless steel floor chain type, infrared heating and three spray tables. The spray gun is fully automatic spray gun imported from Germany, which is equipped with automatic powder recovery system through electrostatic adsorption. The daily output can reach up to 20000 pieces.

Advantages: digital control, high efficiency and stable quality.

Automatic stretching line

The body or house is produced by automatic drawing, with high dimensional precision, fast processing speed and stable quality. It is suitable for mass production, easy engineering arrangement, high economy and operation safety.

Dust-free workshop

In order to ensure that the filter system itself is not polluted and protect the diesel engine fuel system to the maximum extent, each of our five and six fuel filters are assembled and tested in a strict clean workshop.

According to the “dust free workshop management system”, each part must be cleaned before entering the dust-free workshop from the material spray room, so as to ensure the cleanliness requirements of each part.

Personnel wearing and going in and out of the dust-free workshop shall be carried out according to the “dust-free workshop management system”.

Automatic stamping equipment

Continuous die system is an automatic stamping mould, with high dimensional accuracy, high processing speed, high material utilization rate and stable quality; it is suitable for mass production, easy engineering arrangement, high economy, and easy to ease the work hardening of drawing materials, and has operation safety.